Home »

Production of boxes and packaging with custom design and printing

Regardless of the size of your business and the market it operates in, your products should always be in the company of sturdy, user-friendly and perfectly printed packaging. Whether it’s a promotional campaign or an expensive and luxurious product, the box is crafted precisely to the standards of the business and the expectations of the customer.

Check our price: it’s free and it only takes seconds!

Express manufacturing & delivery even for complex projects

438 papers available to showcase your work in an extraordinary way

A variety of sizes, finishes and bindings to suit your needs

Competitive rates

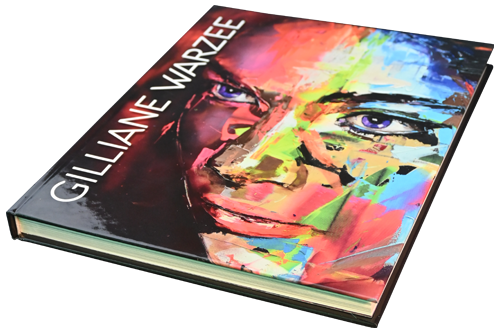

Make your book stand Out

The Options

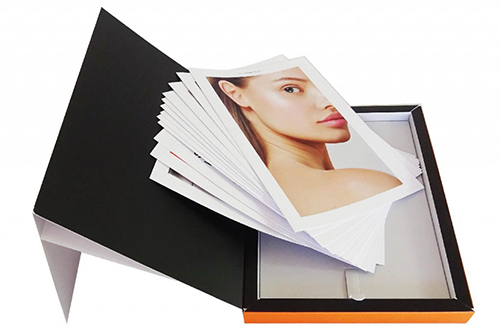

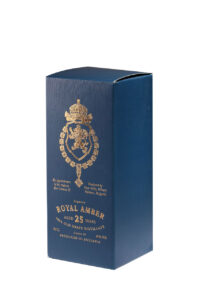

Luxury packaging

Is your product different and really special? Will it be part of the world of luxury? This implies that the packaging in which it falls into the hands of your potential customers must be on the same level. It should neither understate nor overstate its contents. Luxury packaging should be like a natural extension of what you produce and make people connect with the product.

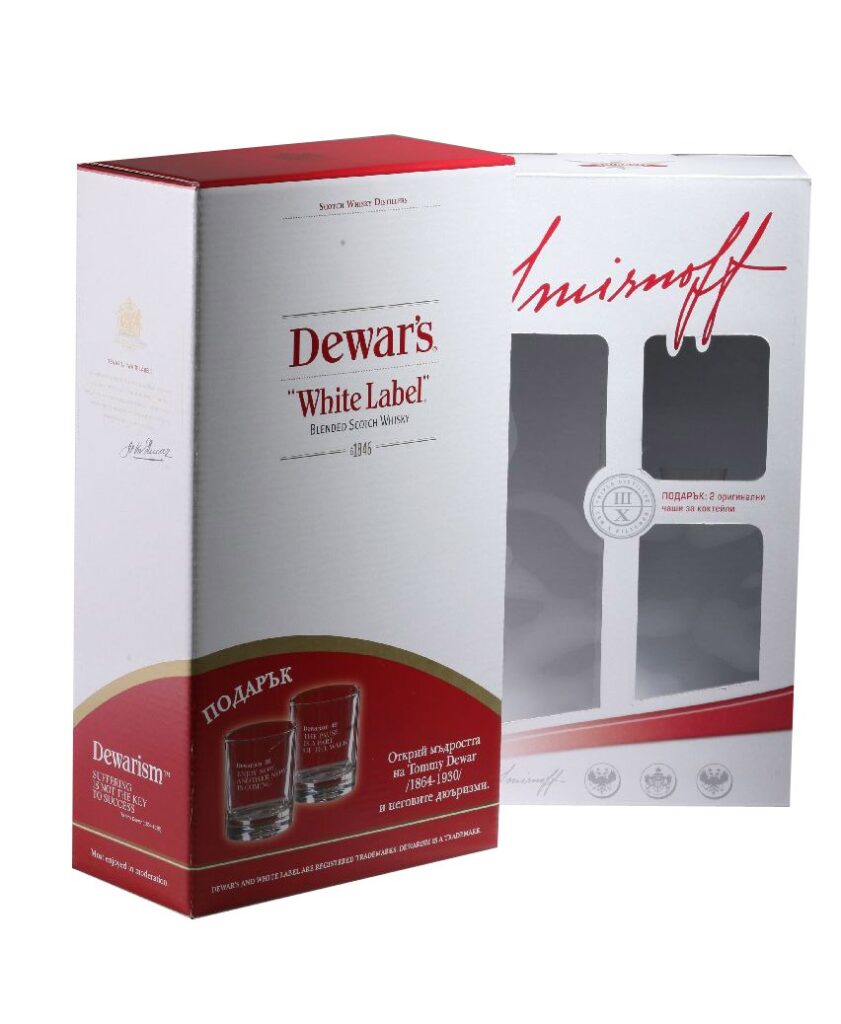

Promotional packaging

Creating promotional boxes and packaging for your business needs for the times of the year when you want to make an impression and give your brand more added value to shoppers. Your goal is to stand out, be remembered and build long lasting relationships? Let’s get started!

Enhancement

Lamination

✔ Laminate mat

✔ Laminate gloss

✔ Laminate satin

✔ Non-scratch laminate

Varnishes

✔ Selective varnish

✔ Varnish with glitters

✔ Micro relief varnish

✔ Varnish with sand effect

Other

✔ Metallized effects

✔ Hot stamp

✔ Braille

✔ Prege

Questions

It is necessary to know the business purpose that the packaging should fulfill. Whether the goal is mass sales, or you are doing a promotional campaign at a specific time of the year, or you want to highlight the exclusivity of the product.

It is imperative to know what is the product for, which packaging or box is being made and what is the target industry. Depending on the volume and weight of the product, it depends on the material to be used and the construction of the packaging.

Send us a drawing of the packaging and information on the most suitable dimensions with maximum and minimum tolerances? What will be the design? Will there be additional features and enhancements?

At Pulsio we can produce and print laminated packaging and boxes and those made of mukawa with runs up to 50 000. In the case of cartons, the print run depends on the size and can reach up to 1 million. For any questions related to print runs please contact our sales representative.

Packages travel to you folded, boxed or stacked on pallets.

The cost to produce your packaging depends on a few key factors. These are:

The print run

Of course, the print run matters when it comes to forming the final price

The lead time

How long it will take to design the structure and design the print if you decide to outsource these activities to our team.

Printing and effects

The coating of the print and what technology is being used, as well as whether lamination, various foils and other forms of enhancement will be applied.

Accessories

The cost is also influenced by whether the design requires the use of different structural and decorative elements.

In your inquiry to us, let us know what Pantone colors you use. To avoid confusion, the background of the packaging should preferably be Pantone.

Stages

1 – Idea

Most clients come to us with a clear concept and idea. However, if you need advice, we can help you to draw them up.

2 – Construction

In order to prepare an optimal price proposal, we need to know how the packaging will be constructed. For this purpose you have to send us the design/drawing or a sketch. If you cannot do this yourself, we will do it for you.

3 – White layout

We produce a white layout* for you (without printing and lamination). That is, we create a white mock-up of the packaging so you can see in practice how the design will look and whether it will meet your expectations in terms of functionality.

4 – Layout validation

The client validates the constructed design.

5 – Design

It is possible that the client has an idea for the design before the construction is made. If the construction is being made for the first time, the design may undergo some adjustments or a completely new one may be created.

6 – Validation of print

Most often a digital proof** is made if the client wants to make sure that the colors match the set ones. On rare occasions, an actual proof*** may be produced.

7 – Production of the run

After validation of the project electronically, we can proceed to the production of the entire run – fabrication of the structure, printing, lamination, punching, gluing and other finishing activities.

8 – Packing and dispatch

We will fully comply with your packaging requirements and delivery points.

– The white layouts are produced on a plotter and sent to the customer unfolded. The price is set per linear centimeter and logically depends on the size of the packages.

– Keep in mind that in most cases digital proofs are made on high-end card stock (99.9% whiteness), which is more machine-friendly, while the actual printing is on lower-end card stock (78-82%). Therefore, the colors from the digital proof will differ from those of the actual print.

– Real samples are the most accurate way for the customer to see exactly what the finished printed product will look like. They require plate exposure, mounting, paper supply, calibration and offset printing. The print run is done by qualified print specialists. This also makes them the most expensive type of proof.

Additional Information

Constructions

For the production of packaging and boxes, 2-, 3- or 5-ply corrugated and micro corrugated boards are used.

Mashing

- Most often we print on GD board and less often we use GC for more accurate printing, or GT board for greater strength.

- Kraft-microfiber board when the customer wants exceptional strength.

- For the more luxurious executions, depending on the project, mokawa may also be used.

Conventional full-color offset printing

Offset printing uses light-sensitive plates, usually made of aluminum, to transfer a combination of the four main ink colors (cyan, magenta, yellow, black) onto the printed media. In addition to CMYK, Pantone colors, coatings and varnishes can also be used.

HUV Full Color Offset Printing

The printed sheet comes out with inks already dry, colors are layered for unparalleled print density resulting in excellent presentation, brilliance and brightness. Recommended for luxury items that by design need to be enhanced with hot stamping, lacquer selective, etc.

Software

We use world-renowned and award-winning EngView. software to develop the packaging design.

Design construction

There are three options for designing your packaging:

- a design from the EngView gallery can be used;

- customization of a design from the gallery to meet the client’s needs;

- Creating an entirely new design.

Business goals bring us many different manufacturers and retailers, but most often packaging and boxes we make for:

✔ HPP,

✔ Perfumery and cosmetics,

✔ Cigarettes alcohol,

✔ Household chemicals.

✔ Other light industries.

Enquiry Form

Check our price: it’s free and it only takes seconds!