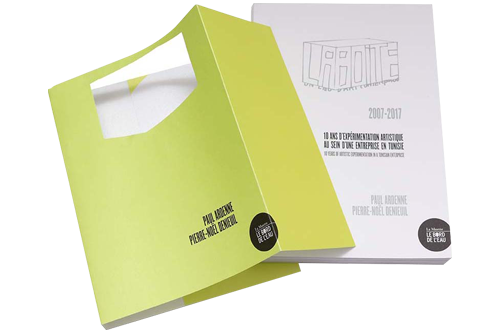

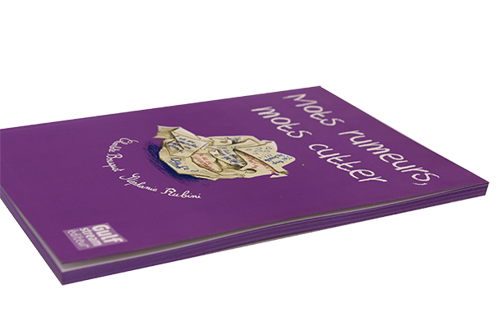

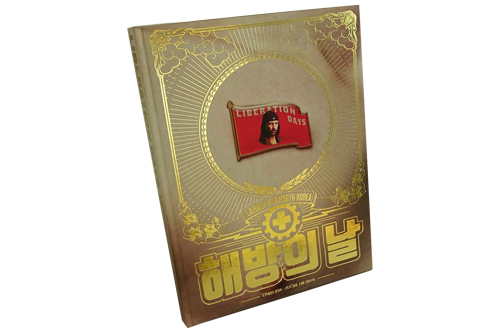

There are some books that make an immediate strong impression on us. Even at first glance they look a cut above the rest: more sophisticated, more elegant – from the premium nature of the paper to the perfect colour finish, from the high-end binding method to the use of techniques such as embossing and gilding, everything about them just says “quality”. This doesn’t happen by accident. To make a book that exudes class requires a book printing and binding company whose workforce are craftsmen, highly skilled and trained experts who have real artistic ability and who take pride in the quality and value of their finished products.

Luxury printing

Pulsio Print is just such a company. Our workforce constitutes your bespoke printing and binding specialists. Our wide range of printing techniques and binding methods ensure that all possible premium options are available for whatever extra touches of luxury you might require. Experience, expertise and advanced technology make Pulsio Print’s craftsmen experts in the production of high-end premium-quality printed end products.

Find the ideal combination of sophistication and finish in your print project with specialist materials and presentation, such as suede and cotton card stocks, white ink on black paper, coloured foil, edge painting, holographic effects, and much more.

We are a creative studio and print factory of 150 people, all with a passion to offer you a unique service and make you and your clients feel special. Museums, art galleries, renowned photographers, fine art publishers, design and creative studios, literary authors – these are our demanding customers, and we take pride in giving them masterpieces. In the world of luxury printing, making an immediate and lasting impression is crucially important, and our goal here at Pulsio Print is to surprise our clients with just how good the finished products that we deliver are.

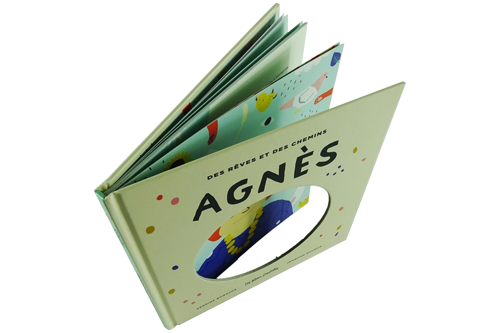

The secret to a great bespoke product is doubling down on the quality and uniqueness. Standing out from the crowd can give you an edge over your competition. Create hardcover or paperback books, catalogues, custom notebooks, and other high-quality print products, all tailored exactly to your needs and with attention to the smallest detail.

The making of luxury illustrated editions can be expensive, but we guarantee you the most competitive possible price for the quality that such a project needs. Remember, you are in full control of your budget, and you have all the information that can help you to make the right decision. Check it out yourself by getting an online quote, using our user-friendly online calculator, or simply request a personal quotation.

Luxury printing

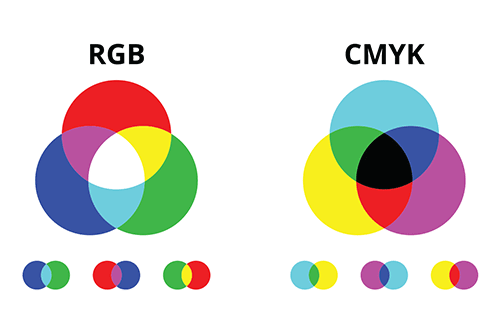

Here is a brief presentation of the printing techniques we provide. You can choose between a wide range of printing methods among which you can find the perfect one for your product, starting with traditional Offset lithography printing, digital printing but also direct UV printing via UV-LED printer, large format printing, volume stickers, direct / UV printing, pad printing, solvent printing, transfer printing, flex, flock, DYE sublimation printing, heat transfer, direct to garment printing (DTG), screen printing. At Pulsio Print, we aim to offer you a 100% quality end product. This means that we work with the best hardware and software to give you consistent colour accuracy (read the full story about consistent, repeatable colour accuracy), the quality materials and the most passionate professionals to deliver the perfect product for you.

Offset lithography printing

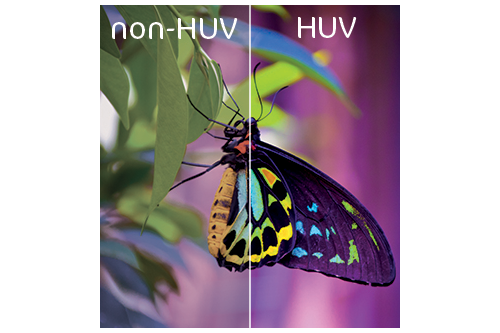

First, we present you the offset printing and the new H-UV luxury offset printing technology. We use the latest Komori H-UV offset printer to ensure consistent colour accuracy and more upscale feel of the final product. This printing technology provides an impeccable rendering and superior brightness and sharpness compared to conventional offset printing.

Traditionally, the offset printing is suitable for larger runs, specialty ink, paper or larger paper size and if you don’t need your printed projects right away.

On the other hand, if you need a small number of copies, need your printed projects quickly, and special features like color, ink, paper size, and paper type don’t really matter, you should opt for digital printing for which we use 2019 Xerox B&W and Color printers.

If you want to know more about the differences between Offset and Digital printing, you can consult our article.

Screen printing

This technique is known by many names – screen printing, serigraphy, silk printing. They all refer to the same thing – a millenary method that consists of using screens to transfer colours. It offers good clarity of details, vivid colours, and exceptional coverage of the print. You can print on materials of any shape, thickness and size. The price lowers in the long run prints.

There are different types of screen printing, depending on your project. This technique is most commonly associated with different goods like T-Shirts, lanyards, balloons, bags and others.

Direct to garment printing (DTG)

This method specializes in highly detailed short production run prints on cotton fabrics. DTG has many benefits over other traditional printing techniques. Its large range of colour options means that you don’t have to compromise as with other printing methods. It is perfect for one-time production runs. The process is entirely eco-friendly, which can be a huge factor when advertising to specific audiences. DTG can also be associated with other printing, cutting and finishing techniques.

Heat transfer

Heat transfer can be done using either screen or digital printing, and in specific cases even using both. This is one of the best-known ways of fabric decoration. The process is fast for bulk quantities and becomes inexpensive with the long runs. Heat-transfer printing adapts well on paper, but it is also perfect for applying images to a range of materials including garments, textiles, physically hard objects like mugs. Heat-transferred images are durable, heat and water-resistant.

DYE sublimation printing

Sublimation printing is characterized by a process in which a substance is converted from solid to gaseous state without passing through a liquid phase. Changing the solid ink particles into a gaseous state, it is a fun and cost-effective way of personalizing your products. The high-quality end products of this printing method have seen their popularity increased due to their thickness and robustness. You can choose between a full range of colours for your project. You can use the sublimation printing technique on a number of materials such as poly cotton and polyester textile, polymer, ceramic, PVC, coated aluminum, polymer-coated metal and plastic and more. However, it is not suitable for 100% cotton materials or other natural materials.

Flock

Flock printing or also called flocking, is a printing method in which short fibers of natural or synthetic material are applied to an adhesive-coated surface. This is one of the only screen-printing methods that alter the texture of the print itself, adding a velvet or suede-like texture to the surface in bright and vivid colours that won’t get washed out. Due to the way flock is printed, the finished printed design is slightly elevated from the garment that shows off an air of professionalism and style. It comes in a basic range of colors that you can combine together.

Flex

With flex printing, the design is cut from a colored foil and then pressed onto the surface under high temperature. The possible colors are limited, but are very vivid and don’t get washed out. Flex printing is perfect on thick fabrics and materials. It adapts well on natural and synthetic materials. This method has the best result on big printing surfaces. Detailed designs are not possible with flex printing. It is suitable for small runs.

Transfer printing

Transfer printing can reproduce high quality and complex images. It consists of printing your design in full colour, after which it is transferred to the desired surface. This is one of the best methods to use for full-colour prints. This is why it’s more interesting to use it for designs with 4 or more colours, including designs with a photograph.

This printing method adapts perfectly on glass surfaces and synthetic materials such as promotional bags, backpacks, umbrellas, hats, etc.

Solvent printing

Solvent printing is perfect for your project if you need vivid colors and pixel-sharp image reproduction. At a microscopic level, solvent actually bites into the print media, ensuring an exceptionally strong, wear-resistant bond. You can choose to print on wood, glass, metal, plastic, fabric, ceramics and many other materials.

This printing technique offers photorealistic print quality, and offers features like glow effects, gradients and others that cannot be achieved with other more traditional methods.

Pad printing

Pad printing, tampography or tampo printing, is an indirect offset printing process. This technique works on the principle of gravure printing, meaning that the printing surface is embossed. It offers the possibility to print on some of the most unprintable products imaginable, turning the pad printing process into a well-established technology. This printing technique is excellent for delicate products. It provides perfect clarity on detailed designs or smaller surfaces such as barcodes and labels.

Direct / UV printing

UV printing is a type of digital printing that uses ultraviolet lights to dry the ink as it is printed. Because there is no absorption on to the printing medium, the dots of wet ink do not get a chance to spread out once printed, resulting in much finer detail and sharper colours. What is more, UV dried inks offer increased resistance to fading. This type of printing is eco-friendly because no solvents are being released into the air. You can print on a number of materials including nonporous materials like plastic, glass and metals.

Volume stickers

Sticker printing is a cost-efficient way to promote your business and boost brand recognition. They have a wide range of applications, as the customer can mount them on various surfaces such as metal, wood, leather, plastic, glass and more. Doming stickers are UV resistant and do not turn yellow. The polyurethane coating preserves the brightness of the colors so they will remain bright and vivid. Thanks to their exceptional flexibility and elasticity, they can also adhere to slightly rounded and contoured surfaces. A three-dimensional sticker will be noticed much faster than a simple, flat sticker. It will give your offer a much more upscale feel.

Large format printing

Large format printing is used to produce large graphics for marketing, branding, and advertising purposes. It can take many forms, but things such as construction site hoarding graphics, fleet and vehicle vinyl wraps, and printed retail graphics and displays tend to be some of the most common uses for the format. It involves the use of specialized equipment, and much bigger printers than standard commercial modules. You can choose to print in small or bigger quantities. This technique offers the possibility to print on different types of materials such as paper, PVC, self-adhesive foil, vinyl, canvas, fabrics and many others.

Direct UV printing via UV-LED printer

UV-LED printing is an easy way to create your customizable products. Cost-effective, it offers an outstanding image quality, higher customer margins on finished goods and high resistance to external weather conditions. UV inks are highly resistant to scratches, wear and tear, and sun exposure than the other traditional printing methods, ensuring a long life of printed images.

UV-LED printing is a one-step process where the ink is directly applied to an object and instantly cured by UV light. It offers the possibility to print on items with texture and dimension, including ADA-compliant signage with Braille, PVC, plexiglass, glass, wood, metal, leather, carpets and other non-standard materials.

Get incredible results with luxury paper

There are many beautiful examples of the very finest paper available. You are sure to get incredible results with our range of specialty papers. There are several factors to consider when choosing paper, such as the product type and the printing technology being used, as well as the feel of the paper, its transparency, and its weight. To help you with your selection, here are the features of the most commonly used papers:

Luxury and designer paper

We offer the widest range of art designer papers such as Fabriano/ Fedrigoni, Arctic Paper/ Munken, Antalis/ Arjowiggins, Sirio Black Black/ Fedrigoni, Mirage suede/ Ratchford, Century cotton wove/ Fedrigoni, Imitlin/ Fedrigoni, Murillo/ Fedrigoni, Splendorlux mirror/ Fedrigoni, Symbol pearl/ Fedrigoni, Aquerello/ Fedrigoni, Cocktail/ Fedrigoni, Constellation Jade/ Fedrigoni, Ispira/ Fedrigoni and much more. Popular choices are a pearlescent luxury texture or highly tactile printing paper with a hammer effect felt mark; either way, you won’t believe the incredible results you obtain with high-quality paper and our luxury printing solutions. However, if you want to double the creativity you can opt for different printing materials: cloth, textile, plastic, ceramics, metal, wood, etc.

Here are some examples:

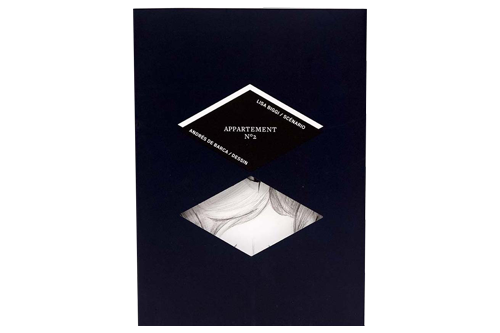

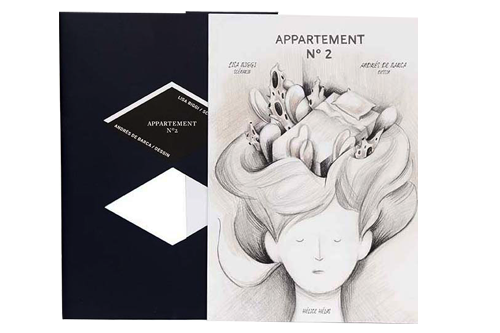

Black paper

Black paper is available with Spot UV, colored foil, or even white ink, printed in either matte or glossy finish. This is a bold choice compared to regular white and off-white colored paper that will surely leave a lasting impression.

Suede paper

Hard suede paper is one of the best kinds available pushing the limits of how soft and luxurious a print can be. It is unique in every way. With a suede print you are sure that your clients will remember you. The suede is soft and luxurious to the touch and at the same time rigid and robust for durability. The textured paper has a soft, raised matte finish providing a strong appearance similar to velvet. It is available in a wide range of colours and patterns. An edge painting could be a very nice addition to the final product.

Cotton paper

Cotton paper gives a simple white paper stock a touch of elegance. It consists of pulp paper with cotton fiber creating a pillowy texture that reacts perfectly to 3D details. For an incredibly beautiful finished product, we can print either digitally or with letterpress stamping. Cotton paper is known for its purity, durability and permanence. It lasts longer and holds up better under repeated handling conditions making it less likely to discolour than some other types of paper. This product is perfect for artists who want to create a fine work of art that will last.

Recycled paper

To contribute to protecting the environment, Pulsio Print offers a wide range of recycled paper such as Arjowiggins, Cocoon and others. These papers are made with 100% recycled fibre, and have a natural design and authentic texture. Recycled papers are strongly opaque, with matt lamination without uncomfortable glare, ideal for printing high quality text and images.

Metalized paper

Silver/Gold: This type of finish is elegant and pleasing to the eye. It can be applied to any size and weight of paper, making sure your print job matches the high quality of your product.

Hologram/ fluorescent: Besides the classic solutions in gold and silver, we produce our own metalized paper and holograms.

Metalized hologram transparent film: We offer an almost endless variety that might make your choice very difficult: crystals, sequins, bubbles, water drops, hearts, flowers, diamonds…

3D Metalized paper: Give more boldness to your printed materials by using this impressive effect. The geometric shapes stand out with the contrasts of matt/gloss and shadow/light, combined with a metallic glint.

Metalized paper with glitter film: This technique adds a brilliant effect to your product for a daring printing solution.

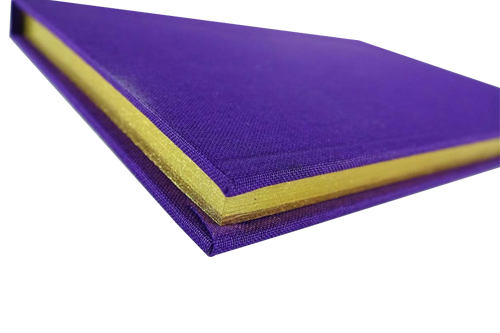

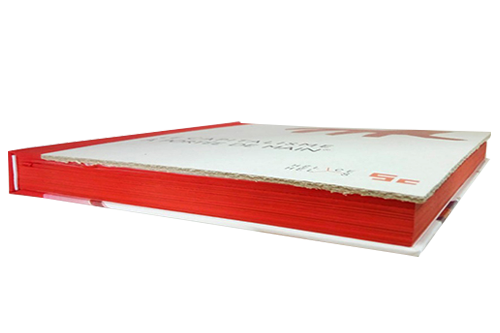

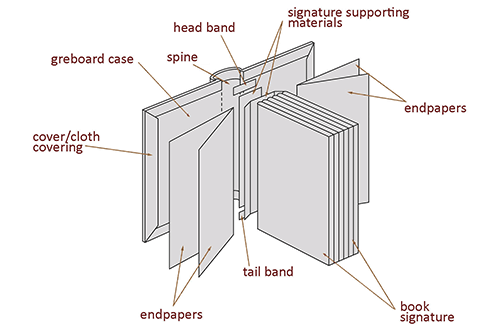

Binding techniques

The quality of the cover reflects the overall quality of the printed product. All of our available options for covers and bindings are designed with three things in mind: easy handling and storage of the printed product, optimal comfort while reading and protection from damage during use. Our binding facility is fully equipped for a range of different techniques and focused on improving the efficiency of order completion. Our aim is to offer you a variety of options that meet the purpose of your printed product, 100% of the time.

Depending on the type of product, which may be portrait or landscape, the binding can be done at the top or left in a range of standard or custom sizes. Products that can lie flat or fold fully right around when opened is extremely important in many contexts.

The main binding methods are glued (perfect bound), sewn, stapled (for low page counts), spiral, Japanese stab binding, screw binding and case binding.

Special finishes

Add more value to your printed products. Make them more attractive by choosing from the various laminates, varnishes or special finishes we offer! Take advantage of the unique expertise and creative technology that we have developed through years of producing art books, catalogues and graphic novels. These are some of the finishes you can opt for when printing your premium products:

Die cutting

Die-cutting gives your book a completely unique look and makes it stand out from any other product. The process is used to cut shapes out of the inside section of the material, rather than trimming the edges. Laser cutting is a similar technology, used for the same purposes, but with even finer results, and is a non-contact method of paper-cutting. Pulsio Print offers both methods of cutting depending on your project, budget and preferences. Read more about this technique.

Varnish

Different types of varnish offer a more economical alternative to lamination, or as a compliment to it. Varnishes increase the strength and durability of the printed product, while also adding an aesthetic sheen. There are UV, UV spot, raised, glitter and micro relief varnishes.

Hot stamping

This is a flexible process using foil that allows you to mark a variety of different materials including plastics, rubber, leather, fabrics, paper and others. It gives your product a luxurious finish. With the possibility of being printed on stocks of dark color such as black paper, coloured foil will give your artwork a shimmer and glow, which is perfect for logos and bold fonts.

Edge painting

Edge painting gives life to your prints on all edges with different colours. This technique gives the perfect touch of elegance and helps your products stand out from the rest. The surest way to give it an out-of-the-ordinary look is to make its outer edges different from those of other books, either by colouring, by gilding, or with a pattern. Popular choices include business cards with painted edges.

3D printing

Embossing and debossing are two techniques that create a three-dimensional image which is either impressed onto or depressed into the paper. These fashionable print options are ideal for giving a new, contemporary look to your print. They can be combined with other effects, like foil stamping, to transform a great product into a luxury one.

Embroidery

Embroidery doesn’t require any printing. Instead, a design is stitched into the fabric by a machine, achieving a 3D effect. This is one of the most popular methods for long-lasting garment branding due to how professional it looks. It resists very well to cleaning and sunlight.

You have an unlimited choice of colors and combinations. Possibility to work on ready-made clothes, hats, bags, gloves and other products made out of cotton, polyester, viscose, lamella.

In addition, you can provide us your logo, which can be additionally sewn or glued to the desired item. It is suitable for small quantity orders.

Laser engraving

Laser cutting and engraving open up unlimited possibilities for paper finishing. Cut out and make bespoke items with our laser cutting machines. Pulsio Print is able to cut and engrave complex contours and designs, fast and with extreme precision.

From spot varnishing, intricate cut-outs and letterpress to silkscreen, hot foiling and embossing there is a range of solutions to help your prints stand out from the crowd. The combinatorial options available for luxury printing create an exponential number of effects that can be generated for all kinds of applications. We offer a full range of luxury printing solutions, plus you can choose between a number of materials and finishes to further enhance your product. Our professional approach allows us to give each of our clients detailed personal attention. We are able to achieve efficiency and speed using the latest technology combined with time-honoured printing methods. Our print works can be delivered all over the world!

For your unique product with your personal artistic vision you need the perfect execution: impeccable printing on a high-quality material accompanied with flawless binding…

Contact us

Our dedicated team will work together with you to come up with a unique design tailored only for you, to outline your individuality and elegance. Start creating today!

Check our price: it’s free and it only takes seconds!