As with everything in the modern world, printing has been changed by the arrival of the digital era. But not as much as other industries, because traditional printing is still important. The drive for fast turnarounds, variable-data print runs, and print-on-demand has led to the development of high-quality digital printing presses. This has created new options and technical advancements. So is modern digital always better than traditional mechanical? The answer is no, and this article will tell you why.

difference between digital printing and offset printing lies in the way the text and images are transferred onto the paper. The two different ways lead to different results and costs.

Here you will find all the details you need to make the right choice for your project. You will be talked through the technical differences of the two types of printing, why their results are different, their advantages and disadvantages, and which types of project they are most suited to, with a detailed checklist to finish so that you will be completely on top of all you need to know to make the right decision.

Offset Printing

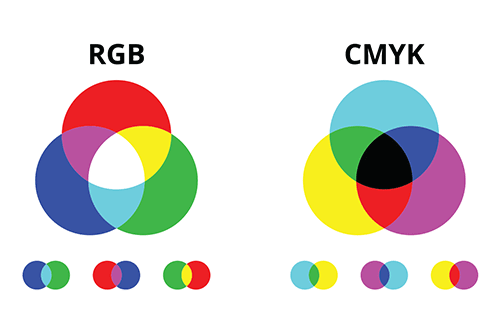

Offset lithography, to give it its traditional name, uses metal plates to transfer a combination of four ink colours, traditionally cyan, magenta, yellow and black (CMYK), onto the medium being printed. Nowadays custom colours such as Pantone colours are also used, as well as coatings and varnishes.

Offset printing works by using large plates, usually made from aluminium, one plate for each of the four colours. The required end result is burned onto the plates and then transferred from the plates to rubber rolls, and only then to the printing surface. It’s called ‘offset’ because the ink isn’t printed directly onto the paper from the plates. The process works because oil and water don’t mix. The areas of the plate that make up the printable surfaces receive ink from the ink rollers, while all other areas receive a film of water, thus keeping them ink-free.

Once the print design is spread onto the rubber rollers, the paper (or other medium) is run through them to complete the printing process.

Digital printing

Digital technology eliminates the need for aluminium plates and rubber rollers, and instead applies the print design directly to the surface to be printed, with liquid ink or a powdered toner. The process is a scaled-up version of the standard home or office inkjet or laserjet printer.

Digital printing uses four electrostatic rollers (sometimes called drums) to apply the four ink colours onto the paper. The rollers use an electrostatic charge that attracts toner or ink. This is applied to the paper and then fused to it by passing it through a high-heat unit.

The advantages of offset printing

Highest possible image quality

Offset gives much better colour fidelity, meaning the accurate representation of the correct colours and their balance in the design. Offset printing can use custom colours, including the entire Pantone range, so as to get all the colours exact. The process ensures clean text and images without streaks or spots.

Suitable for almost any kind of material

Offset can be used with a wide range of surfaces including wood, cloth, metal, leather and plastic, as well as all types of paper and custom finishes.

The unit cost goes down as the size of the print run increases.

It costs more money to set up an offset printing project than a digital one, because the plates have to be made up (etched and burnt) and then brought into the system, which then needs to be run for a while on scrap sheets of paper until the plates and rollers are properly inked, all of which takes time and therefore money. However, once everything is set up it costs less to print each individual unit than it does with digital printing, whose costs are the same per item whatever the print run. This efficiency after the setup means that offset printing is the best choice for large runs. Given the high colour-quality of offset printing, this constitutes excellent value for money for full-colour printing in high quantities, and is much more economical than digital for more than 500 copies. Both the ink and each sheet of paper are cheaper than those of digital presses. The savings kick in at higher volume: > 300 copies for colour Color and > 500 copies for B&W.

Offset printing can run at speeds up to ten times faster than digital. But unlike the toners of digital printers, offset printing uses wet inks, which need to dry before the cutting, folding and binding process. This means that smaller print runs can take longer to produce than digital printing. (But see our article on HUV technology for how Pulsio Print can speed up this process and make it even more efficient.) For larger print projects the speed of the process after the setup gives maximum efficiency.

The advantages of digital printing

Perfect for smaller print runs

Unlike offset, digital printing can print one item – from one sheet to one book – with minimal setup. If you want to print 100 copies of a 200-page catalogue, you will be printing 20,000 pages but making 100 items. Given the speed of setup and the lack of need to make plates for all the content of the 200 pages, digital printing is the best way forward for such a project.

Unlike the wet inks of offset printing, digital printing delivers each page with the ink dried and ready for binding or, for a small item such as a flyer, immediate use. Digital is therefore ideal for print runs less than 300 in colour and less than 500 in B&W, and those where there is a tight deadline for production.

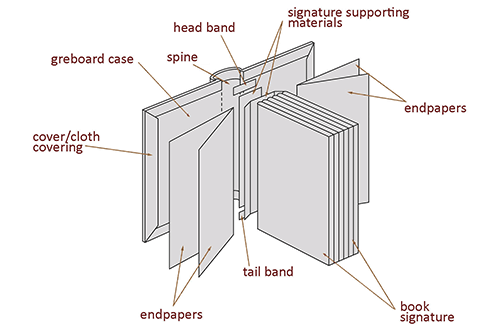

However, printing the pages is only one part of the overall process because you still need the binding in order to get a finished product, and binding also takes time. If you add special finishes on the cover, like soft touch or a 3D effect, this adds additional turnaround time.

Customisable and personalisable

Variable data printing, such as direct mail campaigns where every name and address is different each time, can’t be done with offset printing. The only way to achieve this is with digital technology. Variable data printing includes personalized images, text and graphics: with modern computing technology, the options are unlimited. You can produce several print runs of the same advert for a concert tour, changing the date and location for each run.

Every item is identical.

Traditional printing can produce costly waste, and variations from copy to copy due to the balance of ink and water during the run. Digital technology removes the possibility of mechanically-induced variations.

Possible disadvantages of offset printing

Offset printing is more technically demanding than digital, and needs more carefully controlled initial parameters. The designer must make the original files with proper colour separation, needing a good understanding of the processes involved, increasing the amount of pre-press work required.

Turnaround times are often longer, since printing time on the press must be booked, and the plate creation process is time-consuming. Checking hard copy proofs for colour, design, pagination and text accuracy can be an important part of the printing process, which takes much more time and costs more with offset than with digital printing.

High cost of low-quantity print runs.

No chance to fix an error once the plates have been set up. If a typo or other issue is noticed after this stage the costly and time-consuming process must be started again from scratch.

Possible disadvantages of digital printing

Far fewer options for print media, only standard paper types.

Much lower colour fidelity away from the simplest RGB colours. Pantone colour inks cannot be used. Digital is unsuitable for high-quality image rendering such as for works of art.

High cost for large-volume print runs, as each copy costs more individually than equivalent offset-printed items.

Slightly lower quality and sharpness in general, for both text and graphics.

Printing projects better suited to offset printing

Large quantity runs of 300+ items

Projects where the highest quality of colour printing is required

Projects using Pantone colours

Books and catalogues using speciality and designer papers

Items with special binding or die-cuts

Magazines and high-circulation newspapers

Large non-variable direct mail campaigns

Printing projects better suited to digital printing

Small print runs

Posters and flyers

Variable data projects such as mailshots

Fast-turnaround projects

Print-on-demand

Items where colour fidelity is not important

So which do you choose?

If your business deals in frequent, fast turnover, constantly-changing low-volume print projects and variable data mailshots then always use digital printing, especially for flyers, posters, one-off event brochures, and in-house booklets.

If your business deals in large print runs of items that don’t change their content very often if at all then choose offset printing, especially if colour quality is important.

If you have a variety of different projects then use this checklist to decide on the best option for each project:

Quantity

How big is the project? If cost is a factor in your decision, then large print runs should be offset printed, small ones digital. As each printed item is cheaper with offset printing than with digital, but the setup costs are much greater, there is a specific number of copies per project before which digital is always cheaper, and after which offset gives the best value for money.

However, the higher cost of a small print run might be required if high-quality colours, Pantone colours or special effects are needed.

Printing medium

If you want speciality or designer paper, special effects, or are printing on something other than paper then offset is the only option.

Colour

Digital printing always uses four-color. If you need only black ink or one additional colour offset printing may come at a lower price if the print run isn’t too small. Choose offset for perfect colour fidelity and Pantone colour inks. If you want metallic or flourescent inks offset is the only option.

Proofs

Do you need to check a physical sample copy before starting the print run? To make just one such copy, offset printing will need to complete the whole print setup process of making the plates etc. which will be expensive if amendments are then made. An offset physical proof of 8 pages, A5 format costs £120. Digital printers can just run off one copy without fuss. But if you know you have the final version and PDF-signoff is fine, then this isn’t an issue.

Are you making hardback books with jackets?

The high-quality colour rendering and fidelity of offset printing will make a better-quality book jacket than digital printing.

Newspapers and magazines

Unless the circulation is small, offset is the correct option.

Size

Digital presses have a smaller maximum paper size than offset presses, usually up to either 19 or 29 inches. Offset presses can print 40-inch sheets. If you have a project that needs large sheets, such as large accordion-folded documents, then offset may be a requirement. Standard sizes such as A4, especially where there are no bleeds, will be handled well by digital printers.

Turnaround

Digital printing delivers the final goods faster than offset. Offset always takes time to set up, while digital printing can be done last-minute if required.

Special effects such as a 3-D effect, available only in offset, will also add extra manufacturing time compared to digital.

Customisation

An offset print run always produces the same content. Digital runs can be customised with variable data, images, names, etc.

Summary

Both offset and digital printing have their advantages and disadvantages, depending on the type of project, the size of the print run, the type and fidelity of colours required, whether special effects are wanted, whether or not cost or turnaround times are important factors, if PDF-signoff is fine, or you need a printed proof, and whether or not you want constantly changing, variable results or will stay with one design for the lifetime of the project.

Use the checklist above to decide what’s best for you for each print project. Pulsio Print’s expert advisers are available to talk you through all the options available for your project, and give you all the pricing details you need, including for each size of print run which option is the most cost-effective. Contact us now for more details!

Pulsio Print’s expert advisers are waiting to hear your ideas to guide you through the many choices and options available to comic book lovers from 7 to 103 years old!

For more information, see the page dedicated to the production of comic books.

Check our price: it’s free and it only takes seconds!